TRADE NAME

Tsujii Seisaku-sho Co.,Ltd.

REPRESENTATIVE

CEO, PRESIDENT: Kazuo Tsujii.

LOCATION

Head Office/Casting Part

1-32-9, Motogo, Kawaguchi-shi, Saitama,

332-0011, Japan

- TEL:

- +81-48-222-3363

- FAX:

- +81-48-223-7480

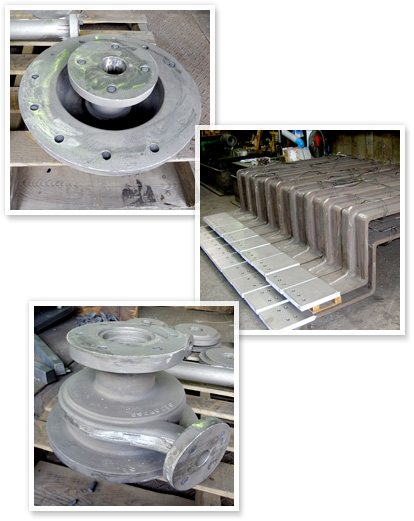

Ariron division

TEL:+81-48-222-5086

FAX:+81-48-223-7480

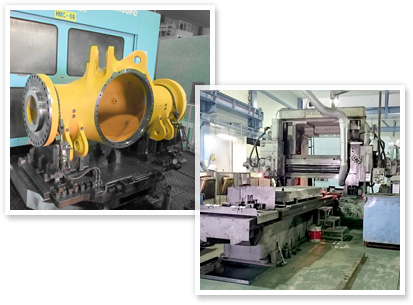

Welding and Machining factory

1-16-44, Suehiro, Kawaguchi-shi, Saitama,

332-0006, Japan

- TEL:

- +81-48-222-5057

- FAX:

- +81-48-222-5058

Niigata Welding factory

Sekikawa-mura, Iwafune-gun,

Niigata large section of a town Tatsutashin,

262nd area, 959-3271, JAPAN

- TEL:

- +81-254-64-1425

- FAX:

- +81-254-64-1427

THE BUSINESS HOURS

8:00-17:00

※Weekday only(There is an exception)

DESCRIPTION OF BUSINESS

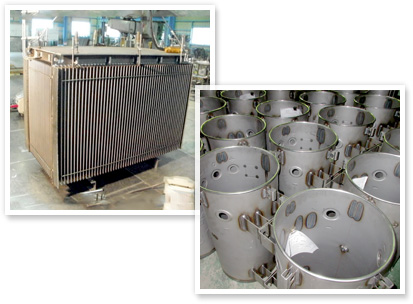

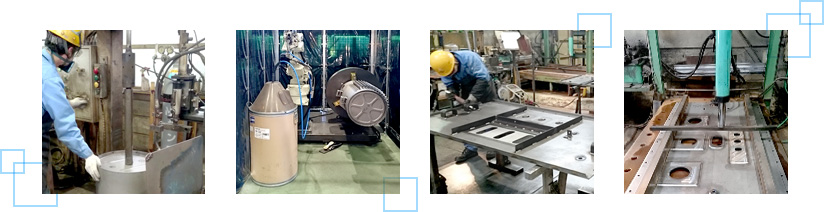

Casting section

Production and sale of a cast product for machine tool parts

Production and sale of a cast product for parts of construction equipment

Production and sale of a cast product for elevator parts

Welding section

Production and sale of the can manufacturing product public, a transformer case on the pillar

and guide-rail Production and sale of a pleasure boat chartered vessel stand and a

construction equipment part

ESTABLISHMENT

Starting: 1919

Establishing: August, 1943

CAPITAL

10,000,000yen

THE NUMBER OF EMPLOYEES

150 people (※ January, 2020)

MAIN CLIENT

Aida Engineering, Ltd.

Komatsu Ltd.

Hitachi Building Systems Co.,Ltd.

Hitachi Industrial Equipment Systems Co.,Ltd.

Toshiba Corp.

Mitsubishi Heavy Industries, Ltd.

KITASHIBA ELECTRIC Co.,Ltd.

TAKAOKA TOKO Co.,Ltd.

Sansei Kenki Co.,Ltd.

Minami Electric Co.,Ltd.

Nippon Yakin Kogyo Co., Ltd.

JFE Steel Corp.

SANKO PUMP MFG Co.,Ltd.

And more